The sugarcane is a rain-fed crop, and so is grown without any irrigation. Processing of the naturally grown chickens takes place on-site before selling to customers across north Queensland. From an energy perspective, the chicken processing is the significant user, and with plans for increased production, was the focus of the audit.

Farm Profile

A North Queensland poultry farm processing 2500 birds per annum could benefit from a recent energy savers audit.

Based on the goals of the farmer, the audit recommendations considered the expected three-fold increase in production while minimising energy consumption onsite, with consequent cost and emission reductions.

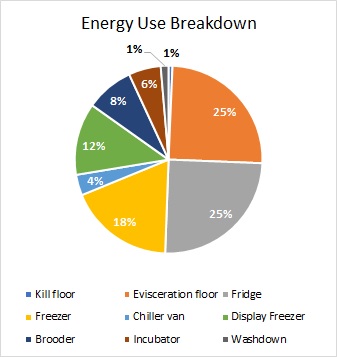

Cooling, from the use of evaporative, heat exchange, refrigeration condenser contributed 70% of overall energy consumption, 40,190kWh per year at a cost of $10,822.

To reduce energy consumption and costs onsite recommendations in the audit explored both current and projected production, and included the following, with a total capital cost of $44,169;

- A review of the current operating tariff.

- Assessing the cool room and freezer areas.

- Air curtains and strip curtains at doorways.

- External fridge unit cooling.

- The engine drive generator.

Table 1. Audit recommendations and savings for current and increased production.

| Solution | Estimated Cost to Implement ($) | 2500 Birds/Annum | 7500 Birds/Annum | ||||

| Energy Savings (kWh) | Cost Savings ($) | Emission Savings (tCO2-e) |

Energy Savings (kWh) | Cost Savings ($) | Emission Savings (tCO2-e) | ||

| Division for freezer to reduce area 3m x 4m | 5,500 | 1,590 | 430 | 1.3 | 1,908 | 515 | 1.5 |

| Install 2 air curtains & 4 strip curtains | 5,600 | 3,477 | 939 | 2.8 | 4,867 | 1,314 | 3.9 |

| External Insulated covers x 4 | 8,500 | 4,900 | 1,300 | 4.0 | 4,900 | 1,300 | 4.0 |

| 30kVA Engine drive generator | 24,569 | 6,717 | 2,015 | 5.4 | 10,075 | 2,720 | 8.2 |

|

Total |

44,169 | 16,684 | 4,684 | 13.5 | 21,750 | 5,849 | 17.6 |

External refrigeration units work best if they are not in direct sun and have a good air flow around the units. Some methods of achieving this is installation of an insulated roof cover, and in some cases a temperature activated exhaust fan can disperse the hot air from the unit.

It is generally recommended to fill 75% of a cold room space to maintain an efficient operation. Maintaining a generally full cold room (rather than empty of variable) can reduce the energy required by approximately 20% for fridges and freezer units. By increasing production the space that is being cooled will be reduced.

The audit suggested that should production decrease the farmer could fill the cold room with a liquid such as water in food grade 1000 litre tanks to act as a thermal mass. If this is not possible it may be possible to divide the area in two with strip curtains or installation of a smaller cold room unit. This will require some detailed analysis of peak and off-peak production.

An engine drive generator to power the refrigeration unit may be worth considering and used during peak tariff peak times, when multiple units are running at full load. Additionally, this could offer some security should power outages or grid instability occur. Modern generators should include programable operation to start-up and consider pass through capability on the invertor if solar or batteries is part of the system.

Based on the current energy consumption of 40,190kWh, a 40% increase in energy consumption would be expected to cater for the increase in production. At the current rate of energy consumption, to increase production to 7500 birds would require 56,266kWh of power. A 38% reduction in energy consumption from the same recommendations would reduce this to 34,516kWh. The capital expenditure required to improve efficiency is $44,169 regardless of production output. With an increase in production the average payback improves from 5.9 years for 2500 birds to 4.8 years when 7500 birds are processed.

At current production levels a 41% decrease in energy consumption could be realised by installation of all recommendations in the audit, with emission savings of 13.5 t CO2-e per year.

Energy Audits for your Business

An energy audit is a great way for a business to cut costs and boost productivity.

An energy auditor will review your past energy bills, your equipment and the way your business operates. They’ll show you where you’re using excess energy and explain what you can do about it. Find out about what’s involved in an energy audit HERE.

See our range of agricultural energy efficiency case studies HERE and Subscribe to our bi-monthly energy e-news HERE

If you have any energy efficiency related questions for the team get in touch at energysavers@qff.org.au.

The Energy Savers Plus Extension Program is delivered in by the Queensland Farmers Federation with support and funding from the Queensland Department of Energy and Public Works.